UV-curing

Photoassisted oxypolymerization of alkyd resins: Kinetics and mechanisms

A new three-component system for photoassisted oxypolymerization of alkyd resins containing a drier, a photosensitizer and a radical generator was investigated. Polymerization profiles were recorded by real-time infrared spectroscopy for a thin film exposed for 1 h to simulated sunlight radiation. The kinetic results showed that the system follows complex kinetics. Multiple regression analysis was used to model the influence of the drier, the photosensitizer and the radical generator on the final conversion and total polymerization rate during photooxidation. The mechanisms involved were studied through laser spectroscopies. Laser flash photolysis was used to measure the rate constants of reaction between the radicals formed from the photodissociation of the radical generator and the model compounds of alkyd resins, leading to the rapid formation of hydroperoxides. The photosensitizer was expected to produce singlet state molecular oxygen that reacts on the alkyd resin, and time-resolved chemiluminescence technique was used to determine the quenching rate constant of singlet oxygen by model compounds. On the basis of these results, a mechanism for the photoassisted oxypolymerization of alkyd resins is proposed that account for the all the different reaction pathways.

Personnel: Ye G.; Courtecuisse F.; Allonas X.; et al.

Source: PROGRESS IN ORGANIC COATINGS, 2012, Volume: 73 Issue: 4 Special Issue: SI Pages: 366-373

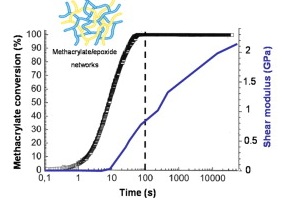

Kinetic study of photoinduced quasi-simultaneous interpenetrating polymer networks

InterpenetratingPolymerNetworks (IPNs) based on a dimethacrylate and an epoxide are synthesized by photopolymerization. By varying the relative amount of radical photoinitiator with respect to the cationic one, and by changing the exposure conditions, it was found possible to delay or accelerate the photopolymerization of the methacrylate monomer compared to the epoxide one. The effect of the relative rate of photopolymerization on the final conversion, glass transition, and morphology is discussed. Finally, the increase in shear modulus as a function of irradiation time was investigated by real time ultrasonic reflectometry. An increase in the mechanical properties after the exposure was evidenced as a consequenceof the living character of the cationic polymerization.

Personnel: de Brito M.; Allonas X.; Croutxe-Barghorn C.; et al.

Source: PROGRESS IN ORGANIC COATINGS, 2012, Volume: 73 Issue: 2-3 Pages: 186-193

Photopolymerization process of UV powders. Characterization of coating properties

The aim of the study was to correlate the characteristics ofUV powder resins with the photochemicalprocess and the final coatingproperties. RT-FTIR spectroscopy equipped with an environmental cell was implemented to follow photopolymerization reactions ofUV powder systems under temperature control. The influence of additional acrylate monomers into UVpowders was assessed and linked to thepropertiesof the final coatings. An increase in concentration of reactive functions was found to lead to higher reactivity, even for relatively low working temperature. Glass transition temperature, crosslinking density and resistance towards scratch and solvent have been investigated and were found to be significantly improved, even for systems exhibiting a non negligible amount of unreacted groups after the curing step. These results highlight the interest of such coatings for heat-sensitive substrates like wood based panels largely used in the furniture market.

Personnel: Maurin Vanessa; Croutxe-Barghorn Celine; Allonas Xavier

Source: PROGRESS IN ORGANIC COATINGS, 2012, Volume: 73 Issue: 2-3 Pages: 250-256

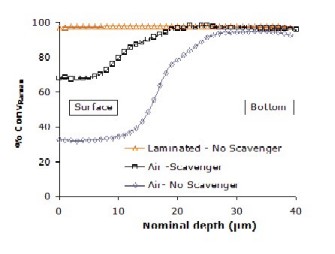

Zirconium Complexes to Overcome Oxygen Inhibition in Free-Radical Photopolymerization of Acrylates: Kinetic, Mechanism, and Depth Profiling

The photopolymerization process of acrylate coatings initiated by visible light (λ > 380 nm) and performed in air was studied in the presence of zirconium complexes. Depth profiling experiments were performed using confocal Raman microscopy showing that the conversion, which is low at the surface of the sample, increases with increasing depth and reaches a full conversion close to the substrate. RT-FTIR spectroscopy corroborates Raman results in evidencing the efficiency of some zirconium compounds to reduce oxygen inhibition. Finally, laser flash photolysis experiments revealed that the beneficial effect in air is attributable to the reaction of the zirconium complex on the peroxyl radicals formed from the reaction of oxygen with radicals. Therefore, the oxygen present in the medium is depleted, allowing a better efficiency of the photopolymerization process.

Personnel: Courtecuisse Francois; Belbakra Abdelhalim; Croutxe-Barghorn Celine; et al.

Source: JOURNAL OF POLYMER SCIENCE PART A-POLYMER CHEMISTRY, 2011, Volume: 49 Issue: 24 Pages: 5169-5175

Depth Characterization of Photopolymerized Films by Confocal Raman Microscopy Using an Immersion Objective

The depth characterization of photopolymer films by confocal Raman microscopy is often troublesome due to refraction effects. To minimize these effects, we used an oil immersion objective and a method was developed to avoid penetration of the oil without damaging the sample surface. Since the surface may be sticky if oxygen in the air inhibits the photopolymerization, a protective layer could not be put onto the film. Therefore, the method consists in using a thin polypropylene foil as substrate for the coating and placing the sample upside down under the objective. In this manner, the immersion oil could be deposited on top of the polypropylene. The advantage of this setup is that the oil, polypropylene substrate, and photopolymer film have close refractive indices. Basic calculations showed that the depth resolution is hardly affected in that configuration and double-bond conversion profiles could be plotted as a function of reliable nominal depth. The validity of the methodology was confirmed by experiments carried out with a dry metallurgical objective on the sample surface, face up, where refraction effects are still minor. In addition, infrared spectroscopy, which was used to follow the photopolymerization, corroborated the Raman conversion of the films over their thickness. The confocal Raman microscopy method can be applied to various photopolymerized systems to characterize their behavior towards oxygen inhibition and other heterogeneities in conversion arising from inner filter effects or interactions between additives for instance.

Personnel: Courtecuisse Francois; Croutxe-Barghorn Celine; et al.

Source: APPLIED SPECTROSCOPY, 2011, Volume: 65 Issue: 10 Pages: 1126-1132

Overcoming the Oxygen Inhibition in the Photopolymerization of Acrylates: A Study of the Beneficial Effect of Triphenylphosphine

Triphenylphosphine (TPP) was used in free-radical UV-curable resins to reduce oxygen inhibition effect. The relative influence of concentration, monomer viscosity, light intensity and sample thickness on TPP efficiency was investigated by real time infrared spectroscopy. It is shown that TPP is an effective oxygen scavenger. The mechanism was investigated by means of Laser Flash Photolysis.

Personnel: Belon C.; Allonas X.; Croutxe-Barghorn C.; et al.

Source: JOURNAL OF POLYMER SCIENCE PART A-POLYMER CHEMISTRY, 2010, Volume: 48 Issue: 11 Pages: 2462-2469

Evaluation of the Exothermicity of Free Radical Photopolymerization through a RT-FTIR and PhotoDSC Study

The exothermic reaction of free radical photopolymerization can affect the curing speed of photocurable resins. This effect was investigated for three different acrylic monomers with increasing functionality. The maximum rates of polymerization and the conversion degrees were analyzed by real time FTIR (RT-FTIR) spectroscopy and photo Differential Scanning Calorimetry (PhotoDSC). For the RT-FTIR experiments, the change in temperature was monitored by following the absorption of a specific band of a polypropylene film which is dependent on the temperature. PhotoDSC experiments were carried out at different temperatures in order to study their effect on the resulting polymer.

Personnel: De Brito Milena; Courtecuisse Francois; Allonas Xavier; et al.

Source: JOURNAL OF PHOTOPOLYMER SCIENCE AND TECHNOLOGY, 2010, Volume: 23 Issue: 6 Pages: 765-769

Formation of Simultaneous UV-cured Interpenetrating Network (IPN)

Acrylic monomers are the most widely used in UV curing because of their high reactivity, their low volatility, their avaibility and their moderate costs. Nevertheless, these compounds are really sensitive to the atmospheric oxygen and the shrinkage is important. The increase in density can yield to stress, distortions and even cracks. Epoxides monomers are known to exhibit low shrinkage phenomenon because of their polymerization by ring opening and they are able to polymerize in the dark after a short irradiation step. However, their low polymerization rate as well as their sensitivity to humidity turns out to be shortcomings for some industrial applications. To overcome the limitations of both acrylate and epoxy photopolymerizations, interpenetrating polymer networks (IPN) based on UV curable multifunctional monomers are attractive systems. Basically, these monomers polymerize by different mechanisms and independently from each other which lead to a material with complex features. The goal of this study is to get a good understanding about the formation of epoxy / acrylate IPN and to establish relations between the phase morphology, the mechanical properties and the irradiating conditions.

Acrylic monomers are the most widely used in UV curing because of their high reactivity, their low volatility, their avaibility and their moderate costs. Nevertheless, these compounds are really sensitive to the atmospheric oxygen and the shrinkage is important. The increase in density can yield to stress, distortions and even cracks. Epoxides monomers are known to exhibit low shrinkage phenomenon because of their polymerization by ring opening and they are able to polymerize in the dark after a short irradiation step. However, their low polymerization rate as well as their sensitivity to humidity turns out to be shortcomings for some industrial applications. To overcome the limitations of both acrylate and epoxy photopolymerizations, interpenetrating polymer networks (IPN) based on UV curable multifunctional monomers are attractive systems. Basically, these monomers polymerize by different mechanisms and independently from each other which lead to a material with complex features. The goal of this study is to get a good understanding about the formation of epoxy / acrylate IPN and to establish relations between the phase morphology, the mechanical properties and the irradiating conditions.

Personnel: Miléna De Brito, Céline Croutxé-Barghorn, Xavier Allonas

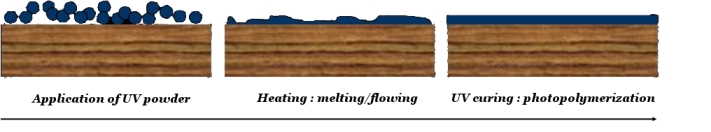

UV Powders

UV powders are solid formulations that can be cured under UV light. These systems combine advantages of both conventional powder coatings (thermal curing) and liquid UV formulations (UV curing). UV powders represent interesting systems to fulfil environmental legislations. Indeed, this technology does not require any solvent or any liquid monomers with small molecular weight (highly volatiles and often irritating). Moreover, if overspray happens during the application step, there is the possibility to recycle this excess of powder.

Application of UV powders is usually done by using an electrostatic spray gun (Corona or Triboelectric) on the object surface. Fluidisation of the solid formulation is first required in order to separate the grains and consequently improve the performance of the system.

Contrary to classical powders, melting and curing of UV powders are two separate processes. The first step consists to heat the coatings at moderate temperatures (by convection, IR irradiation or combination of both) thus allowing the melting and flowing of UV powders and resulting in the formation of smooth films. No thermal curing occurs at this stage. While the melt film is still hot, crosslinking is performed during a second step upon exposure to UV light. The whole process, including spray application, is not a long time process; few minutes are generally enough.

Since temperature of the melting of UV powders does not generally exceed 120ºC, the process allows to coat heat sensitive substrates such as plastics, wood or derivatives, preassembled parts or large mass parts.

The present study focuses on the comprehension of the reactivity of photocurable systems for wood substrates. A mechanistic approach is developed to understand how UV powders are reacting during the curing process and is combined with a thermomechanical characterization of the final coatings.

Personnel: Vanessa Maurin, Céline Croutxé-Barghorn, Xavier Allonas

Support: ANR Poudrabois ANR Precodd 2008

Collaborators: CRITT Bois, Lermab, AkzoNobel Powder Coatings, ECOFIA, Ober, Frachon

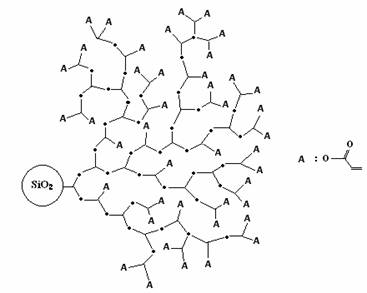

Radical photopolymerization in presence of hyperbranched polymers

Hyperbranched polymers represent a class of dendrimers whose macromolecular architectures is less symetric and monodisperse in size than conventional dendrimers. they are synthesized by polymerization of ABx type monomers (x=2) in one-step, leading to mostrly spherical structure, highmy brnached and mulficunctional through the numerous terminal functions localized at the surface.

Hyperbranched polymers represent a class of dendrimers whose macromolecular architectures is less symetric and monodisperse in size than conventional dendrimers. they are synthesized by polymerization of ABx type monomers (x=2) in one-step, leading to mostrly spherical structure, highmy brnached and mulficunctional through the numerous terminal functions localized at the surface.

When incorporated in the UV-curable formulation, hyperbranched polymers can advantageous in regards to several aspects:

- First, they can decrease the risk of entanglement of molecular chains in these globular structures, therby decreasing the viscosity of the formulation. A reasonable viscosity is essential to facilite the spreading of the formulation, teh wetting of teh substrate, thus avoiding problems of sagging (Condition of a paint that runs down a vertical surface, giving an effect of horizontal wrinkles. )

- Hyperbranched polymers are characterized by a high functionality, which may favour a high density of reticulation, which is related to the mechanical properties of the film

- The presence of terminal and superficial functions provides the hyperbranched structures wityh better solubily compared to traditional multifonctional oligomers.

Personnel: Abraham Chemtob, Céline Croutxé-Barghorn

Support: Polyrise

Collaborateurs: Vincent Gaud, Fabien Rouge

Depth Characterization of Coatings by Confocal Raman Microscopys

Radiation curing has been widely used in the last 20 years in the coating industry as this technology offers several advantages over the conventional thermal curing such as no or low volatile organic compounds (VOC) emission, low energy consumption, easy industrial implementation and high process output [1]. However, in the case of radical photopolymerization, the process suffers from inhibition by atmospheric oxygen [2]. Therefore, the structure of the cured polymer is not homogeneous across the depth of the film and a gradient of conversion is observed leading to poor final surface properties [3] (scratch or chemical resistance). Confocal Raman Microscopy (CRM), is a powerful characterization technique whereby the deleterious effect of oxygen on the polymer structure can be studied by performing depth profiling measurements. CRM enables to appreciate the effect of oxygen scavengers on the polymerization and on the polymer structure. The influence of the diffused oxygen from air can also observed by performing experiments in laminated conditions.

Radiation curing has been widely used in the last 20 years in the coating industry as this technology offers several advantages over the conventional thermal curing such as no or low volatile organic compounds (VOC) emission, low energy consumption, easy industrial implementation and high process output [1]. However, in the case of radical photopolymerization, the process suffers from inhibition by atmospheric oxygen [2]. Therefore, the structure of the cured polymer is not homogeneous across the depth of the film and a gradient of conversion is observed leading to poor final surface properties [3] (scratch or chemical resistance). Confocal Raman Microscopy (CRM), is a powerful characterization technique whereby the deleterious effect of oxygen on the polymer structure can be studied by performing depth profiling measurements. CRM enables to appreciate the effect of oxygen scavengers on the polymerization and on the polymer structure. The influence of the diffused oxygen from air can also observed by performing experiments in laminated conditions.

Personnel: François Courtecuisse